Buy Now, Pay Later

- – 6-month term

- – No impact on credit

- – Instant approval decision

- – Secure and straightforward checkout

Ready to go? Add this product to your cart and select a plan during checkout.

Payment plans are offered through our trusted finance partners Klarna, Affirm, Afterpay, Apple Pay, and PayTomorrow. No-credit-needed leasing options through Acima may also be available at checkout.

Learn more about financing & leasing here.

Selected Option

Eligible for Return, Refund or Replacement within 30 days of receipt

To qualify for a full refund, items must be returned in their original, unused condition. If an item is returned in a used, damaged, or materially different state, you may be granted a partial refund.

To initiate a return, please visit our Returns Center.

View our full returns policy here.

Recently Viewed

Style: Saw

Features

- For clean and safe chop and miter cuts in non-ferrous metals, plastics and wood

- Ideal for miter cuts, instead of swivelling the saw head, the table with clamped down work piece is turned

- Continually adjustable round table made of pressure-cast aluminum swivels 45 degrees in both directions with positive stops at 15 degrees intervals

- Integrated tightening mechanism with self-centering clamps, V-groove for round pieces, front side groove for clamping thin work pieces

- Scope of delivery: 1x PROXXON Chop and Miter Saw KGS 80 including carbide tipped saw blade. Part number: 37160

Description

By using the fence and counter-rotating the table 2x 45 degrees, one can get the opposite angles for two equally long framing pieces by simply reversing them. Powerful, very quiet DC motor. Power transfer via belt drive. Carbide tipped saw blade 80 x 1.6 x 10mm (3 1/8" x 1/16" x 3/8"), 36 teeth. Base with round table of pressure-cast aluminum and CNC-machined guides and fittings. Other technical data: Volts 110 - 120V AC, 60Hz. Max. Power 1/4hp (200W). Speed 5,400rpm. Table area 9" x 9" (230 x 230mm). Weight 12 lb (6kg). From the Manufacturer Proxxon Chop and Miter Saw KGS 80 for clean and safe chop and miter cuts of non-ferrous metals, plastics and wood. Ideal for miter cuts. Instead of swiveling the saw head, the table with clampped down work piece is turned. The laterally moving saw head prevents colliding of the saw blade with the vise jaws. This allows for a minimal gap between the work piece vise and the actual cut, which is vibration-free and leaves no burr. Powerful, very quiet DC motor. Power transfer via quietly operating toothed drive belt. Comes with 3-1/8" 24 tooth carbide saw blade.

Brand: Proxxon

Color: Green

Blade Material: High Speed Steel

Surface Recommendation: Wood

Power Source: Corded Electric

Brand: Proxxon

Color: Green

Blade Material: High Speed Steel

Surface Recommendation: Wood

Power Source: Corded Electric

Special Feature: Brake

Included Components: bare-tool

Product Dimensions: 15.55"L x 9.84"W x 12.4"H

Voltage: 120 Volts

Item Weight: 13.2 Pounds

Speed: 5400 RPM

Blade Length: 8 Inches

Number of Teeth: 36

Number of Batteries: 1 Lithium Ion batteries required.

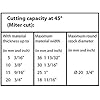

Cutting Angle: 45 Degrees

Wattage: 200 watts

Global Trade Identification Number: 06

UPC: 006274371600 732454713822 796299428044

Manufacturer: Proxxon

Part Number: 83418

Item Weight: 13.2 pounds

Country of Origin: Taiwan

Item model number: 37160

Batteries: 1 Lithium Ion batteries required.

Is Discontinued By Manufacturer: No

Size: 0.5 Liters

Style: Saw

Finish: Matte

Material: Steel

Item Package Quantity: 1

Coverage: 438

Special Features: Brake

Usage: Interior

Batteries Included?: No

Batteries Required?: No

Warranty Description: Limited Warranty of PROXXON Power Tools for home and hobby use. PROXXON Inc. warrants to the original purchaser only that all PROXXON consumer power tools will be free from defects in material or workmanship for a period of two years from the date of purchase. Seller's sole obligation and your exclusive remedy under this limited warranty and, to the extent permitted by law, any warranty or condition implied by law, shall be the repair or replacement of parts, without charge, which are defective in material or workmanship, and which have not been misused, carelessly handled, or mis-repaired by persons other than Seller or Authorized Service Station. This limited warranty does not apply to tools used for commercial manufacturing and construction applications as well as accessory items such as circular saw blades, drill bits, router bits, jigsaw blades, sanding belts, grinding wheels and other related items and accessories. Damage to the product resulting from tampering, accident, abuse, negligence, unauthorized repairs or alterations, unapproved attachments, or other causes unrelated to problems with material or workmanship are not covered by this warranty. Any implied warranties shall be limited in duration to two years from date of purchase. Some states in the U.S. and some Canadian provinces do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. In no event shall seller be liable for any incidental or consequential damages (including but not limited to liability for loss of profits) arising from the sale or use of this product. Some states in the U.S. and some Canadian provinces do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. All warranty claims must be accompanied by a copy of the packing slip, invoice, or other proof of purchase.

Date First Available: September 24, 2008

Frequently asked questions

To initiate a return, please visit our Returns Center.

View our full returns policy here.

- Klarna Financing

- Affirm Pay in 4

- Affirm Financing

- Afterpay Financing

- PayTomorrow Financing

- Financing through Apple Pay

Learn more about financing & leasing here.

Top Amazon Reviews