Ready to go? Add this product to your cart and select a plan during checkout. Payment plans are offered through our trusted finance partners Klarna, PayTomorrow, Affirm, Apple Pay, and PayPal. No-credit-needed leasing options through Acima may also be available at checkout.

Learn more about financing & leasing here.

This item is eligible for return within 30 days of receipt

To qualify for a full refund, items must be returned in their original, unused condition. If an item is returned in a used, damaged, or materially different state, you may be granted a partial refund.

To initiate a return, please visit our Returns Center.

View our full returns policy here.

Size: 4in

Features

Description

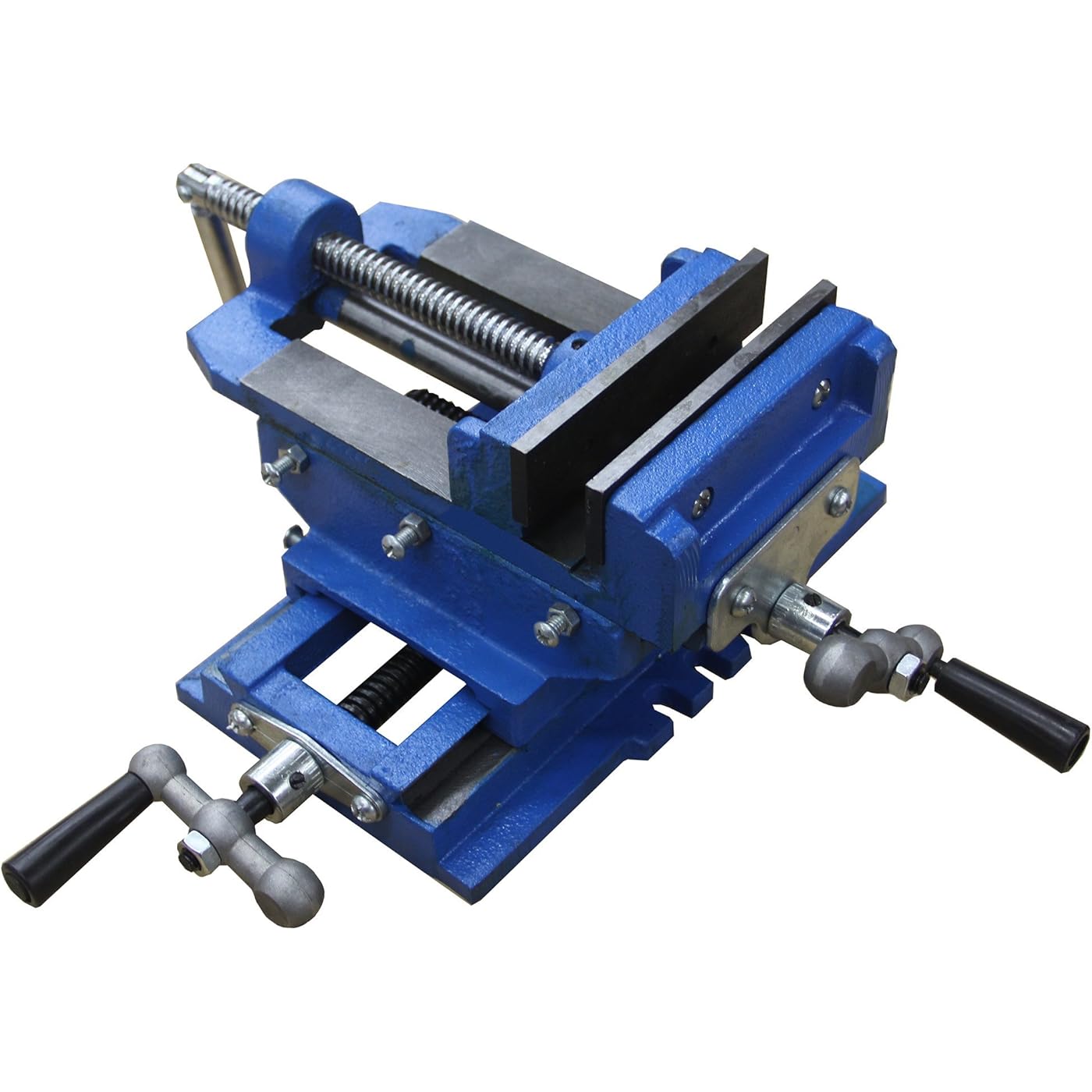

This 4" cross sliding vise will easily turn your drill press into a milling machine. With the vise and its precise moving slider, wood and metal parts can be easily processed with high precision and high quality. It can also be connected to a lathe or other tools to fix the workpiece in the exact position required. Key Points: Durable cast iron construction Powerful serrated steel jaws Cold rolled steel screws 2 swivel crank handles for adjusting vise front to back and left to right Bolt down slots for securing Hinged vise crank handles drops out of the way Designed for woodworking and metalworking Product Specification: 3.5" throat opening, 5" longitudinal and 3.5" cross travel, jaw width: 4" - MaximumVise and cross slide have adjustable shimsCross slides have removable adjusting crank handles

Material: Stainless Steel

Brand: HFS

Item Dimensions LxWxH: 10 x 6.5 x 10 inches

Color: Blue

Style: Modern

Item Weight: 15 Pounds

Manufacturer: HFS

Part Number: 16037

Item Weight: 15 pounds

Product Dimensions: 10 x 6.5 x 10 inches

Item model number: 16037

Is Discontinued By Manufacturer: No

Size: 4in

Color: Blue

Style: Modern

Material: Stainless Steel

Power Source: Manual

Item Package Quantity: 1

Batteries Included?: No

Batteries Required?: No

Date First Available: June 20, 2014